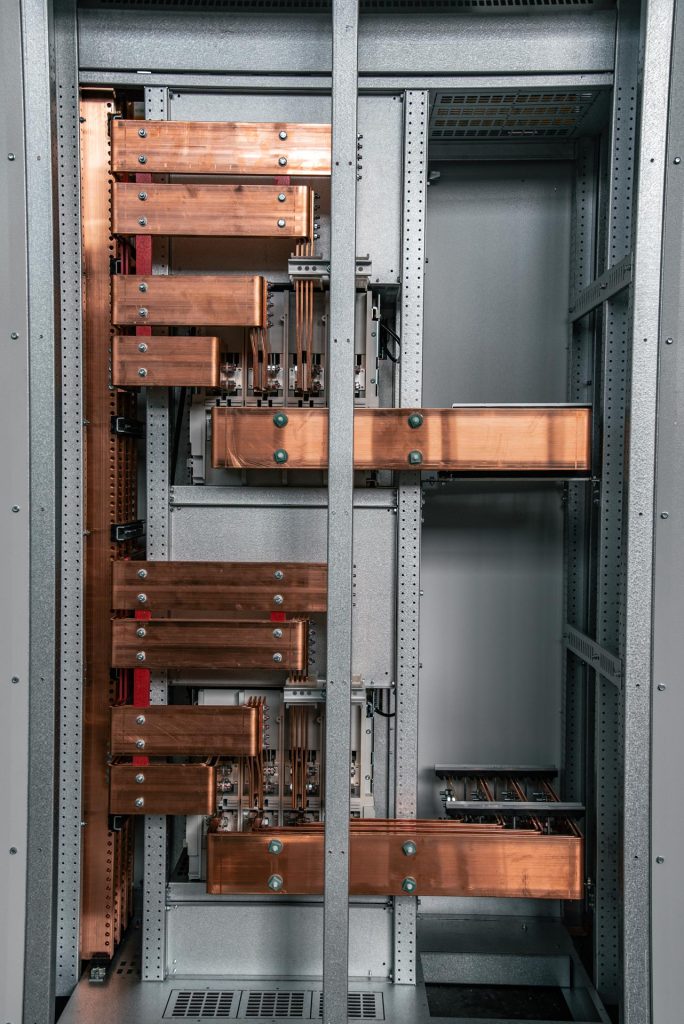

SYSTEM LV2002 Power Center is a LV distribution switchboard particularly suitable for applications requiring high performance and a high level of reliability. They are generally installed downstream the MV/LV transformers or generator groups and contain the main and distribution circuit-breakers of the LV plant.

They consist of standardized section based on a easy-to-fit modular design permitting to suit any plant configurations, electrical diagrams and installation sites.

The wide range of sections and the availability of different versions which ensure both front and rear access, offer different solutions satisfying any need in terms of installation and space requirements. Switching and regulation operations on the equipment, as well as the access and routine maintenance of the switchboard can be carried out in maximum safety for personnel and with no danger of accidental contact with live parts.

Thanks to their versatility and high performance, SYSTEM LV2002 switchboards can be used in power production plants, industrial plants, on installation board and anywhere else are required:

SYSTEM LV2002 switchboard has been designed and built respecting the main international and national standards:

SYSTEM LV2002 switchboards are subjected to the type tests foreseen in the standards. On request the documentation from national and international laboratories are available.

All the switchboards are subjected to the routine tests foreseen in the standard:

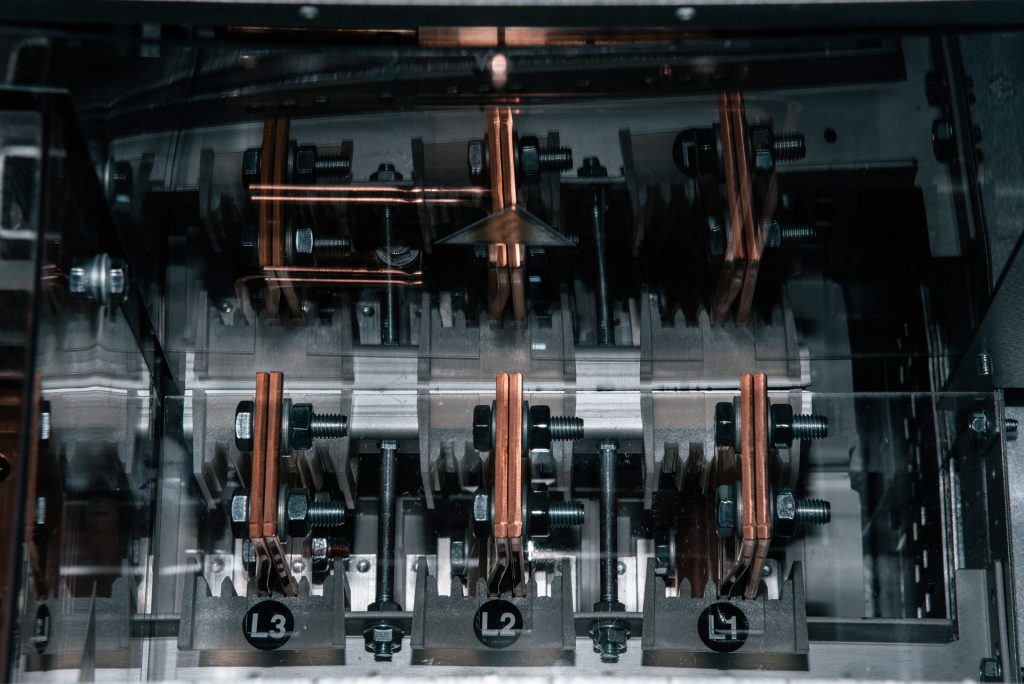

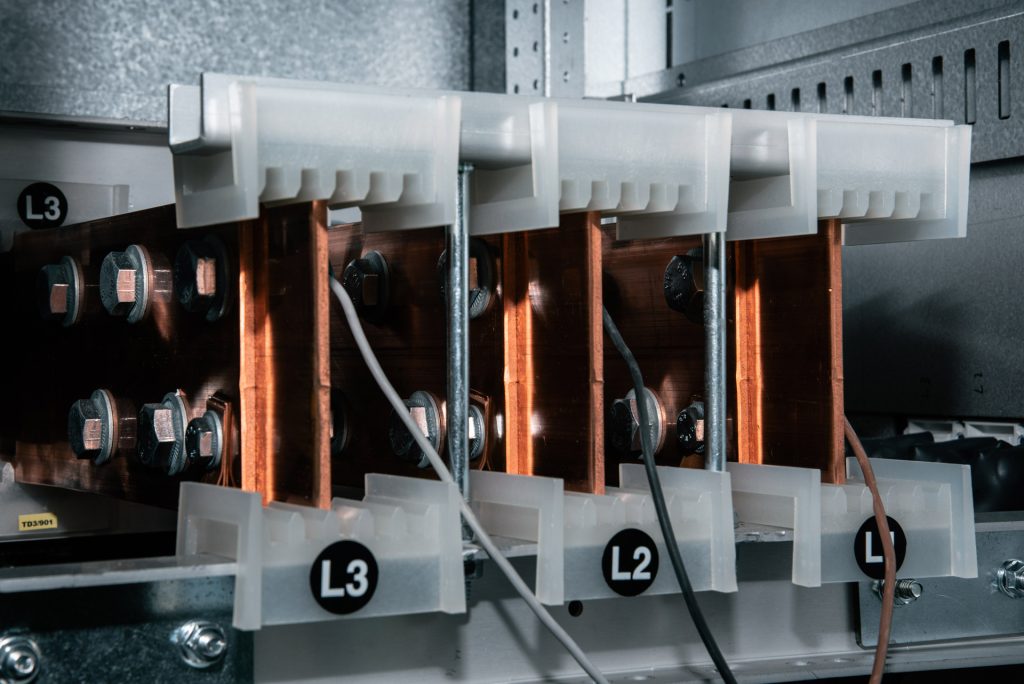

SYSTEM LV2002 section consist of standardized elements whose mode of installation enables operations of modification and/or adaption to be performed in complete safety, without particular settings or tools. The supporting structure has four functional spaces:

These four spaces are enclosed in a metallic casing, whose walls provide protection against contact with live parts and the penetration of liquid and solid foreign bodies (CEI EN 60529).

Modular design guarantees:

| Electrical characteristics | LV2001 | LV2002 | |

|---|---|---|---|

| Rated insulation voltage (Ui) | 1000V | 1000V | |

| Rated operational voltage (Ue) | 690V | 690V | |

| Rated frequency | 50/60 Hz | 50/60 Hz | |

| Rated Current | Main busbars | ≤ 2700A | ≤ 6300A |

| Distribution busbars | ≤ 2200A | ≤ 3200A | |

| Rated short-time current for 1 sec. (Icw) | ≤ 70 kA | ≤ 100 kA | |

| Rated peack withstand current (Ipk) | ≤ 154 kA | ≤ 220 kA | |

| Degree of protection (according to EN 60529) | External enclosure | standard IP31 | standard IP31 |

| With open door | IP2X | IP2X | |

| Maximum number of modules for section | 48 | 48 | |

| Internal separations | forms 2,3,4 | forms 2,3,4 | |

| Protection of surfaces | External enclosure | Sheet steel RAL9002 | Sheet steel RAL9002 |

| Internal structure | (Az-150) - Aluzinc | (Az-150) - Aluzinc | |

| Access | From the front | From the rear | |

| Installation | Against a wall or back to back | With space on the rear | |

| Entry and exit of cables | From top or bottom | ||

| Dimensions of a section | width [mm] | 900,1050,1150,1550 | 600,800,900,1200,1400 |

| height [mm] | 2365 | 2365 | |

| depth [mm] | 600 | 1035,1385,1510 | |

| Protection persons against internal arc (IEC 61641) | On request | On request |

| TEST REPORT N° | TEST SUBJECT | STANDARDS |

|---|---|---|

| CN13S0171058-01 | Corrosion resistance severity A Damp heat cycle (salt spray test) | CEI EN 61439 |

| 11-0766-04 | Lifting | CEI EN 61439 |

| 02SM00037 | Mechanical impact | CEI EN 61439 |

| TR-LM-02/1291 | Protection class of enclosures IP31 | CEI EN 60439 |

| CESI MP 94/026871 -100kA | Protection against electric shock and integrity of protective circuits | CEI EN 60439 |

| Effective earth continuity between the exposed conductive parts of the assembly and the protective circuit |

||

| Short-circuit withstand strength | ||

| 14-0770-02 | Dielectric properties: Rated lighting impulse withstand voltage | CEI EN 61439 |

| 14-0817-01 | Temperature-rise limits | CEI EN 61439 |

| TR-LM-00/0990 | Internal Arc Containment | CEI EN 60439 |

| 2005-0501-00 c | Testing in arc conditions caused by internal failure | CEI EN 61641 |

| TEST REPORT N° | TEST SUBJECT | STANDARDS |

|---|---|---|

| CN13S0171058-01 | Corrosion resistance severity A Damp heat cycle (salt spray test) | CEI EN 61439 |

| 11-0766-05 | Lifting | CEI EN 61439 |

| 02SM00037 | Mechanical impact | CEI EN 61439 |

| 17044-R01 | Protection rating IP55 | CRI EN 60529 |

| TR-LM-99/0910 | Protection class of enclosures IP42 | CEI EN 60439 |

| MI14S0338091-01 | Protection class of enclosures IP43 | CEI EN 60529 |

| TR-LM-99/0803-50kA | Protection against electric shock and integrity of protective circuits | CEI EN 60439 |

| Effective earth continuity between the exposed conductive parts of the assembly and the protective circuit |

||

| Short-circuit withstand strength | ||

| TR-LM-99/0804-70kA | Protection against electric shock and integrity of protective circuits | CEI EN 60439 |

| Effective earth continuity between the exposed conductive parts of the assembly and the protective circuit |

||

| Short-circuit withstand strength | ||

| TR-LM-99/0805 | Impulse withstand voltage | CEI EN 60439 |

| Mechanical operation | ||

| 14-0817-04- LF | Temperature-rise limits | CEI EN 61439 |

| 11-0766/02 | ||

| TR-LM-00/0971 | Internal Arc Containment | CEI EN 60439 |